Introduction

About half a million new cases per year have been recorded with gastric and duodenal cancers majorly linked to H. Pylori infection1. The development of the proper floating retentive system is essential to eradicate H. Pylori since its absorption in the mucous layer is more effective than the basolateral membrane2. Hence Floating Raft System (FRS) was selected to improve gelation, duration, and better drug release for effectively treating this infection. As of literature search, this drug was not developed in the form of FRS. Hence we selected this system to improve its availability at the target site for the eradication of H. pylori. When FRS comes in contact with gastric fluids, a viscous cohesive gel is formed, wherein each portion of the liquid swells forming a continuous layer called Raft.

Several dosage forms were formulated among FRS showed benefits like ease of manufacturing processes, administration, and to float faster with better compliance to the patient3. The problems of bacterial resistance and side effects associated with Amoxicillin could be reduced by formulating gastro retentive FRS, as they provide an appropriate prolongation of drug release near the bacterial ecological niche4).

Design of Experiment (DoE) is an essential statistical approach that can be utilized to optimize and to select compatible stable formulation by the screening of variables. Adopting this technique minimizes the time where the formulation can be optimized by a few trails, thereby reducing the cost of final Amoxicillin product with in-built quality. Hence in the present study, the formula was developed and optimized by 23 factorial design with replicates.

Methods

Preparation of the floating raft system

Sixteen formulations (Table 1) were designed as per 23 factorial design (8 formulations+8 replications, Design expert software version 11.0) and were developed by the method as described below.

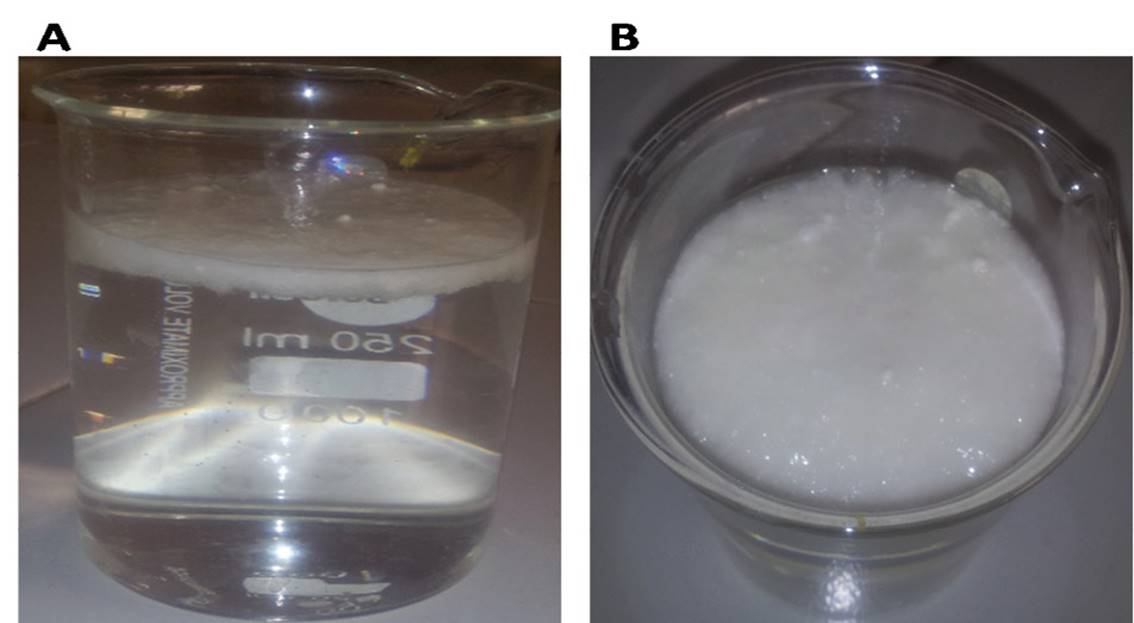

Preparing a dispersion medium in which the guar gum was dispersed in 90 mL of deionized water along with 0.25% w/v-sodium citrate and heated at 90ºC. The medium stirred until it appears as a homogenous viscous liquid. Later cooled to 40ºC and dispersed Amoxicillin drug in the medium and then followed by the addition of 10 mL of calcium carbonate dispersions with stirring. GMS was melted to 90ºC and dispersed it into the above drug incorporated gum formulation by homogenization using a high-speed homogenizer2 (Figure 1).

Table 1. Formulation table of Amoxicillin floating raft system (Factors & responses)

| Formulation | Factor 1 A: Guar gum % | Factor 2 B: Calcium carbonate % | Factor 3 C: GMS % | Response 1 Gelation duration (h) | Response 2 FT Lag time (min) | Response 3 % CDR at 24 h |

|---|---|---|---|---|---|---|

| 1 | 3.00 | 1.00 | 1.00 | 20 | 4 | 90.2 |

| 2 | 3.00 | 1.00 | 1.00 | 20 | 4.1 | 88.4 |

| 3 | 4.00 | 1.00 | 1.00 | 24 | 2.5 | 82.4 |

| 4 | 4.00 | 1.00 | 1.00 | 24 | 2 | 80.2 |

| 5 | 3.00 | 1.50 | 1.00 | 15 | 5 | 84.4 |

| 6 | 3.00 | 1.50 | 1.00 | 15 | 5.5 | 80.7 |

| 7 | 4.00 | 1.50 | 1.00 | 24 | 2.5 | 85.1 |

| 8 | 4.00 | 1.50 | 1.00 | 24 | 1.5 | 90.7 |

| 9 | 3.00 | 1.00 | 1.50 | 24 | 1.5 | 95.4 |

| 10 | 3.00 | 1.00 | 1.50 | 24 | 2 | 94.7 |

| 11 | 4.00 | 1.00 | 1.50 | 24 | 1 | 97.4 |

| 12 | 4.00 | 1.00 | 1.50 | 24 | 1.2 | 94.2 |

| 13 | 3.00 | 1.50 | 1.50 | 24 | 4 | 87.6 |

| 14 | 3.00 | 1.50 | 1.50 | 24 | 4 | 80.7 |

| 15 | 4.00 | 1.50 | 1.50 | 20 | 3.5 | 80.2 |

| 16 | 4.00 | 1.50 | 1.50 | 20 | 3.5 | 85.1 |

Invitro Gelation study

Prepared and collected pH 1.2 dissolution media in vials to maintain SGF (stimulated Gastricfluids) condition at 37±0.5ºC. Add a drop of formulation in each vial and make a visual observation on Gelation lag time (time taken to the formation of gel) and Gelation duration (time taken to dissolve)5.

Measurement of viscosity

FRS viscosity was measured by Brookfield viscometer by changing the angular velocities 10 -100 RPM at 23 ±0.5°C6.

In-vitro floating study

USP dissolution apparatus II was used. 900 mL of pH 1.2 dissolution media was prepared to create SGF (Stimulated Gastric Fluid) condition. 10 mL of in-situ gel formulation was added slowly in each dissolution médium without disturbance at 37±0.5°C, and visual observation was made on floating lag time (time for the formulation to appear on the médium surface) and floating duration (time taken to dissolve gel)2.

In vitro drug release

The study was performed using 0.1N HCl buffer (pH 1.2) and maintained at 37±0.5ºC with 50 RPM. 10 ml of gel formulation was taken into the watch glass and kept in the dissolution medium. The sample was collected at each interval time and replaced the same amount of buffer médium, which was prewarmed and maintained at 37°±5C. Spectrophotometrically measured at 210 nm. All dissolutions were performed in triplicate.2

In vivo Pharmacokinetic studies

A total of 4 healthy rabbits were randomly divided into two groups, and each group consisting of two animals. Group-I: Administration of marketed formulation (EDMOX). Group-II: Administration of optimized FRS. After a single oral administration, 0.25ml blood sample was collected from either left or right marginal ear vein using a 3ml needle at 0, 0.5, 1, 1.5, 3, 4.5, 6, 12 and 24h. Blood samples were analyzed further by HPLC technique for measurement of pharmacokinetic parameters like AUCo-t, Cmax, tmax, and t1/2. The measurements were assessed at p<0.057,8.

Results and Discussion

In the present study, guar gum, calcium carbonate, and GMS were selected as factors and gelation time duration (h), floating lag time, and % cumulative drug release (%CDR) were selected as responses. These were selected based on the literature survey. After selection, preliminary studies were conducted, and the concentrations were fixed, followed by experimentation using the Design of experiments (Factorial design, Design expert software version 11). The study was conducted at 2 levels 3 factors with replications (8) (8+8 total of 16 experiments). It was observed that guar gum and GMS were the significant factors affecting gelation duration, increase in the quantity of both guar gum, and GMS increased gelation duration i.e., sustained gelation period (24 h). Floating time increased with an increase in the amount of guar gum and calcium carbonate, whereas an increase in the quantity of GMS decreased floating time. An increase in the amount of guar gum, calcium carbonate, and GMS decreased % CDR i.e., sustained the release of the drug for 24 h (equation 1, 2, 3). All the desired factors exhibited probability at <0.05, indicating significance at that level (Table 2). In all the cases, the predicted R2 is closer to adjusted R2, and adequate precisión values were greater than 4 and indicated adequate signal. Hence it was used to navigate the design space. A significant factor that affects the formulation was identified by Pareto charts and by cooks distance. Pareto chart is a useful tool to identify statistically significant effects by t-value limits; the effects above the t-value indicated significant factors. The predicted vs. actual values plot revealed that the experimental values were in close agreement with the predicted values (Figure 2).

Gelation duration = -66.00000 + 23.50000 *Guargum +64.0000 GMS -170000 Guargum *GMS --- 1

Floating Lag time = +1.22500 + 0.075000 *Guar gum +7.35000* Calcium carbonate -1.60000*GMS-1.30000* Guargum* Calcium carbonate --- 2

% CDR at 12h = +418.50000-114.60000 *Guar gum -264.20000 *Calcium carbonate -211.60000 *GMS + 89.10000 *Guar gum *Calcium carbonate +79.90000*Guar gum*GMS +170.60000 Calcium carbonate *GMS-62.40000*guar gum *calcium carbonate* GMS --- 3

Table 2. ANOVA representing significance at p<0.05

| Source | Sum of squares | df | Mean square | F Value | p-value | |

|---|---|---|---|---|---|---|

| Model | 112.75 | 3 | 37.58 | 11.00 | 0.0009 | significant |

| A-Guar gum | 20.25 | 1 | 20.25 | 5.93 | 0.0315 | |

| C-GMS | 20.25 | 1 | 20.25 | 5.93 | 0.0315 | |

| AC | 72.25 | 1 | 72.25 | 21.15 | 0.0006 | |

| Residual | 41.00 | 12 | 3.42 | |||

| Lack of fit | 41.00 | 4 | 10.25 | |||

| Pure error | 0.000 | 8 | 0.000 | |||

| Cor Total | 153.75 | 15 |

Contour plots (Figure 3) were used to identify design space; further numerical analysis yielded 12 best solutions based on desirability. To achieve desired criteria, i.e., gelation time closer to 24 h, floating lag time 1-2 min, and % CDR greater than 95%, the factors can be varied at 3.79-4.00 % of guar gum, calcium carbonate and GMS at 1 and 1.5% respectively with the desirability of 0.899-0.902. Calcium carbonate generates gas, which is obtained from calcium. When the formulation comes in contact with stomach acidic pH, carbon dioxide gas is evolved. It shows in situ release along with floating properties because of entrapping of gel network in the formulation and enhance gel floating on the surface of the dissolution medium (Invitro) or the stomach (Invivo). These Ca2+ions are responsible for gelation through a cross-linking polymer chain. Lipid emulsification ameliorated the FRS characteristics. Incorporation of GMS enhanced the gelation efficiency with an increased Gelation period from a few hours to greater than 24h. The AUC 0-t, of the marketed formulation, was found to be 42.27 µg.h/ml. The increase in AUC0-t was observed in the FRS (test) formulation, which was around 68.42 µg.h/ml. This indicated the drug availability for a long duration. The mean peak plasma concentration of test formulationCmax6.97 µg/ml gradually reached in 4 h. In the case of marketed formulation (R), the Cmax was 3.02 µg/ml gradually reached in 3 h. The Cmax of the marketed formulation was less when compared with the test formulation. The increase in tmax indicated drug availability for a prolonged period. The plasma elimination half-life (t1/2) of the marketed formulation was 4.72 h, and the FRS (T) formulation was 5.98 h, which were significantly different. The overall Cmax, tmax, AUCo-t, and t1/2 were completely different between both the test and marketed formulations (Figure 4). Therefore the prepared formulations released the drug for a prolonged period essential for the effective eradication of H. pylori infection.

Figure 2. Diagnostic plots A. Half-Normal Plot B. Pareto chart C. Predicted Vs. Actual D. Cooks Distance E. Box-cox plot for Power transforms

Conclusion

Amoxicillin FRS was successfully developed and optimized by factorial Design with replicates to enhance gastric residence time and drug release to effectively target Helicobacter pylori. It can be concluded that the floating raft system was successfully developed by the Design of experiment (DoE) application with fewer trails & by utilizing easily available excipients for better floating, gelation, and sustained delivery of the drug. Invivo studies exhibited better pharmacokinetic parameters in FRS (test formulation) than marketed formulation that proved extended and prolonged release of drug at the required site for treating Helicobacter pylori.