Key Messages

1. Vacuum technologies allowed the design of a ready-to-eat vegetable-based dish with 200.23 mg EAG/100.

2. The sous vide cooking method used allowed to improve the conservation time in refrigeration.

3. The sous vide cooking kept the microbial load at safe levels for 21 days.

4. Sensory evaluation showed that texture and flavor significantly influenced the overall acceptability of millefeuille.

Introduction

Vegetables are important components of a healthy diet as they are a source of vitamins, minerals, dietary fiber, and phytonutrients. There is a consensus that low consumption of fruits and vegetables is associated with poor health and an increased risk of non-communicable diseases1. People are changing their eating habits by increasing their daily intake of vegetables. However, the consumer who spends less time cooking finds practical problems such as lack of cooking skills, the effort required to prepare vegetable dishes, or a lack of available ready-to-eat plant-based foods, which makes it difficult to incorporate healthy products that contain vegetables2.

Several studies suggest that facilitating consumer access to fruits and vegetables through the design of refrigerated precooked products increases the consumption of this particular food group3. Therefore, the design of precooked plant foods of high nutritional quality can contribute to improving the quality of the diet by helping to overcome these barriers in the preparation of vegetable dishes4. Ready-to-eat plant-based products are attractive to consumers looking for healthy and convenient meals, especially if they contain ingredients that play a specific role in the physiological functions of the human body5.

Vacuum impregnation is a methodology that has been studied to incorporate physiologically active compounds to improve the nutritional quality of vegetables. This technique consists in the exchange of the gas present in the food pores for the external liquid due to the action of hydrodynamic mechanisms (HDM) promoted by pressure changes6. In this study, this methodology was used to incorporate polyphenols into the preparation and increase its nutritional quality. These compounds are currently of great nutritional interest because they contribute to preventing various diseases related to oxidative stress7. Several studies have corroborated the beneficial effect of consuming polyphenols added to a diet rich in vegetables8.

The sous vide (SV) cooking technique facilitates the preparation of ready-to-eat vacuum-packed products and consists in using temperatures below 100 °C for long periods, immediate cooling, and refrigeration at 3 °C until the dish is served. This technique preserves natural sensory qualities and nutritional value and prolongs shelf life. The precise temperature control in this cooking method provides more options for cooking and texture than traditional methods9. Chiavaro et al.10 demonstrated that sous vide cooking of carrots can preserve and/or improve nutritional quality; Iborra-Bernard et al.11corroborated that the samples of sous vide red cabbage were tastier and more purple and that they retained more anthocyanins than those cooked by conventional treatments. Alcusón et al.12 reported that sous vide cooking improved the total phenolic content, antioxidant activity, color, and texture of borage (Borago officinalis L.) stems.

Studies on the mechanisms of spoilage that occur in food during storage are the subject of continuous and exhaustive research. An important aspect of food development is knowing its stability during storage under the conditions determined for commercialization13. In this sense, sous vide technology is capable of increasing the useful life of products in comparison to other traditional methods14. Few published studies have focused on ready-to-eat vegetable-based products cooked by sous vide. However, this cooking technique has been reported for other food matrices, especially products of animal origin15.

In view of these considerations, the aims of this study were to: 1) study were to design a ready-to-eat millefeuille with functional characteristics by applying vacuum technologies, 2) analyze the effect of refrigerated storage on its physicochemical parameters, 3) evaluate the main sensory parameters.

Methodology

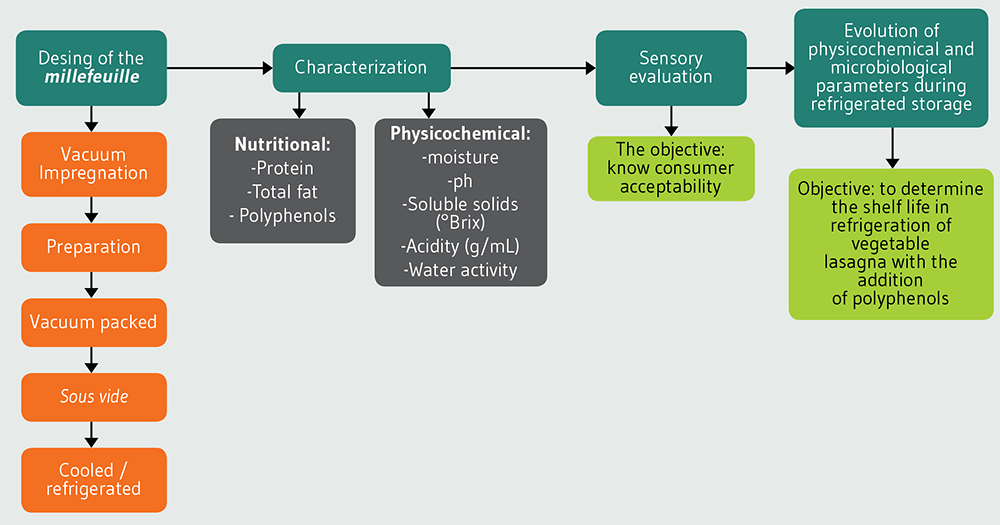

The experimental design was divided into three phases, as shown in the scheme in Figure 1.

Materials

In the design of the preparation, the following ingredients were used: sweet potato (Ipomoea batatas L.), zucchini (Cucurbita pepo L.), dried tomatoes, eggs, powdered milk, cornstarch and Danbo cheese. All the ingredients were bought at the local market. The vegetables were selected considering their freshness, firmness and absence of microbial or mechanical damage. They were sanitized with 0.1% sodium hypochlorite (1 mL/L) and chopped. Sweet potato slices 3 mm thick and 50 mm in diameter were vacuum impregnated (VI) with polyphenols following the technique proposed by Abalos et al.16. The polyphenol solution used was Vitisol® from the national company Nialtec S.A. This polyphenol extract contains 95% oligomeric proanthocyanidins. The formulation of the 3.5% VI solution was made based on the study carried out by Rózek et al.17. For the VI experiments, the Gastrovac® vacuum cooking equipment was used. The sweet potatoes were immersed in the VI solution in the equipment and subjected to vacuum for 25 minutes at 20 °C. Pressure was restored at the same time intervals as that of the LV.

Millefeuille preparation

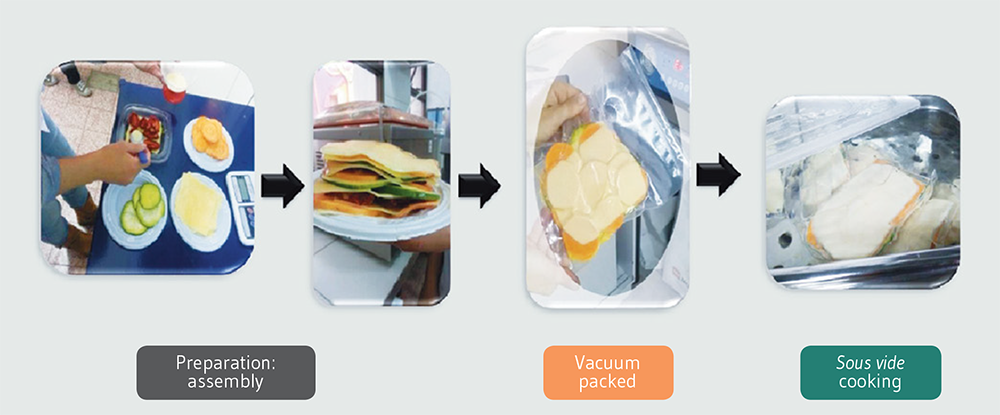

To prepare the millefeuille, the following proportion of ingredients was used: sweet potatoes vacuum impregnated with polyphenols (35%) and Zucchini (24%) in slices 3 mm in thickness and 40 mm in diameter, dried tomatoes (11%), Danbo cheese (21%), and a binder -milk, cornstarch, and egg- (9%). For the assembly, the ingredients were interspersed in layers (Figure 2), resulting in 285 g servings of millefeuille. The preparation was vacuum packed (VACPACK, ICC, 80016™, Spain) in polyamide-polyethylene bags (O2 permeability, 25 to 30 cm3/m2/day; water vapor permeability of 5 g/m2/day). The heat treatment was by sous vide cooking in a constant water-circulation bath with temperature and time regulation (RONER COMPACT, ICC, 80060, Spain) at 80 °C for 45 minutes. It was subsequently rapidly cooled in a water bath at 0 °C for 5 minutes. The cooking temperature was monitored with a thermocouple (HANNA Instruments, HY 93530N, Italy). The cooked samples were refrigerated at 2 °C, until further study.

Physicochemical characterization

The ready-to-eat millefeuille with the addition of polyphenols was characterized physicochemically, in triplicate, as follows, the compositional properties of the SRB were determined according to AOAC (Association of Official Analytical Chemist)18. Moisture content was determined after heating in an infrared drying oven (RADWAG, Mag. 50/WH, Poland) according to 7.003-8421. Protein was estimated by the Kjeldahl method described in AOAC 928.08, with a conversion factor of 6.25 for protein. Total fat was determined by the Soxhlet solvent extraction gravimetric method, following method official AOAC 965.33. Total carbohydrates were estimated by subtraction of the percentage of protein, lipid, ash from the total dry weight.

For polyphenols, total phenol content was determined by the reagent Folin-Ciocalteu method, using the test Heimer, Vignolini, Dini and Romani19. Samples of sweet potatoes of 16 g were processed in a blender with 50 mL of methanol (Sintorgan, Lot. Nº 38931). The homogenates obtained were placed in a beaker and heated at 40 °C with continuous stirring (Barnstead Thermoline) for 15 minutes before centrifugation (Rolco, CM 2036.4, Argentina) for 5 minutes at 11.200 g force and filtration. A 0.5-mL aliquot was added to a test tube together with 1 mL of Folin-Ciocalteau reagent (Biokar) and 10 mL of distilled water, left to stand for 2 minutes. Then, 4 mL of a 20% (w/v) sodium carbonate solution (Merck, Argentina) was added, brought up to a final volume of 25 mL, and heated at 50 °C for 5 minutes in a thermostatic bath (Vicking SRL, Masson, Argentina). The optical density was finally measured in a spectrophotometer (Jenway Mod. 6505 UV/VIS™) at 765 nm16.

The pH was measured using a pH-meter with a combined Ag/AgCl electrode (ORION, S.A. 720, United States). The pH measurement was performed by immersing the electrode in a homogenate of 10 g of millefeuille in 100 mL of distilled water. Soluble solids (°Bx) were estimated using a table refractometer (A. KrussOptronic, Germany) according to AOAC 932.1221. Acidity was determined by the volumetric method. Water activity was measured with a hygrometer (Rotronic, Hygrolab C1, Switzerland) according to AOAC method 978.18.

Sensory evaluation

To determine the consumer acceptability of the product, the smell, color, texture, and taste parameters were evaluated. The millefeuille, cooked the day before tasting and kept refrigerated, was heated to the usual temperature for consumption (65 °C), cut into 5 cm/5 cm portions, and served on white plates. The sensory evaluation was carried out by a panel of 105 people, selected for being regular consumers of ready-to-eat products, in the laboratory facilities of the Faculty of Bromatology, following the ISO 8589 standard20. Consumers were asked to indicate their level of appreciation for the sensory attributes and the overall acceptability of the sample on a 9-point hedonic scale ranging from 1 = "I don’t like it very much" to 9 = "I like it very much." The study was approved by an Institutional review board of the National University of Entre Ríos (RESOLUTION "C.D." Nº 017/17).

Evolution of physicochemical and microbiological parameters during refrigerated storage

Twelve servings of sous vide cooked millefeuille were prepared and stored in a refrigerator (2 °C). The temperature was monitored throughout the storage period with a digital thermometer (Elitech, D-T1, China). The samples were analyzed physicochemically and microbiologically at different times (0, 7, 14, and 21 days) by the determinations reported below.

Physicochemical analysis: Polyphenols and pH were determined following the techniques previously mentioned. Weight variation: samples were weighed using a precision balance (OHAUS, ADVENTURES, Canada), and the weight variation (ΔP) was calculated as the percentage of variation between the weight of the samples on days 7, 14, and 21 with respect to the weight of samples on day 0.

Color was determined using a colorimeter (HUNTER ASSOCIATES LABORATORY, Inc., MiniScan EZ Model, EE UU) in the CIE L* a* b* color space. The variation was evaluated in the parameters L* (black 0, white 100), a* (red-green), and b* (yellow-blue). The color parameters were determined from triplicate measurements in each sample. Color intensity C*ab (Equation 1) and color change ∆E (Equation 2) were calculated, where L0, a0, and b0 represent the readings of the non-impregnated samples.

Texture was determined by a compression test using a texturometer (Instron 3342™, Massachusetts, USA). The values obtained for the maximum compression force were expressed in Newtons (N). The tests were carried out in quintuplicate, with 30% deformation and at a test speed of 0.5 mm/s. The firmness (strength) of the material was calculated from the relationship between the maximum force (N) and the maximum deformation (mm). The elastic modulus was calculated from the relationship between the maximum force (N) and the initial module (mm).

Microbiological analysis: To perform the microbiological analysis of the millefeuille, a 10-g sample was weighed in a sterile bag and diluted with 90 mL of buffered peptone water (Acumedia. Neogen Corporation, Michigan, USA). A 1/10 dilution was obtained after homogenization. Counts were done in duplicate.

To estimate molds and yeasts, a culture medium composed of oxytetracycline, gentamicin, yeast extract, and glucose (OGY) (Merck KGaA, Germany) was used. The inoculated plates were incubated at 25 °C for 5 days, according to ISO 1741021.

To determine total aerobic psychrotrophic bacteria, the Plate Count Agar (PCA) culture medium (Britania, Argentina) was used. The inoculated plates were incubated for 7 days in a cold room at 4 °C.

Determination of total anaerobic psychrotrophic bacteria was carried out in Tryptone Soya Agar (TSA) medium (Oxoid, Basingstoke, United Kingdom). The inoculated plates were placed in an anaerobic jar with a capacity of 2.5 L and incubated in a cold room at 4 °C for 7 days according to ISO 21527-222.

At the end of the incubation period, agar plates with dilutions that allowed the best Colony Forming Unit (CFU) counts were selected. The counts were expressed as log CFU/g of product for the different groups of microorganisms analyzed.

Statistical analysis

The data of the test results are expressed as means ± standard deviations, as computed by the software XLSTAT (New York, USA) program for Windows, version 2018.7.52523. The significance of differences between the means was determined by the analysis of variance ANOVA followed by the Tukey multiple-comparison test with a limit of significance at p<0.05.

Multiple regression was performed to analyze the overall acceptability by considering the influence of the specific sensory attributes (color, taste, texture, and smell), using the Minitab 18 Statistical Software (LLC, United States).

Results

Ready-to-eat millefeuille enriched with polyphenols

This work was based on the design of a ready-to-eat vegetable-based preparation using vacuum impregnation (VI) to incorporate polyphenols and sous vide cooking as the heat treatment (Figure 3).

The physicochemical characterization of the designed culinary preparation is shown in Table 1. The ready-to-eat product obtained provides 200.23 mg GAE/100 g per serving, through the VI.

Table 1. Physicochemical and nutritional parameters of the culinary preparation: ready-to-eat millefeuille with the addition of polyphenols.

| Portion of 285 g | Amount per proportion - Mean (SD) (n=3) |

|---|---|

| Protein (g/100 g) | 18 g (0.32) |

| Total fat (g/100 g) | 15 g (0.24) |

| Polyphenols (mg GAE/100 g) | 200.23 (0.85) |

| Moisture (g/100 g) | 89.79 (0.24) |

| pH | 5.38 (0.03) |

| Soluble solids (°Brix) | 7.10 (0.10) |

| Acidity (g/mL) | 0.19 (0.15) |

| Water activity | 0.99 (0.01) |

Sensory evaluation

For the sensory evaluation, a group of 105 consumers participated in the study, of which 65% were women and 35% men. The age ranges were 18-30 years (54%), 31-59 years (35%), and 60 years or older (12%).

The results presented in Table 2 show the level of satisfaction of each parameter studied. It was observed that the general acceptability, taste, smell and color were indicated in the "I like" category, with color obtaining the highest score. The texture was identified as different from the rest corresponding to the category "I am indifferent about it".

Table 2. Descriptive statistics.

| Sensory characteristics | Vegetable millefeuille - Mean (SD) |

|---|---|

| Global acceptability | 3.56 (0.67)a |

| Taste | 3.90 (0.91)a |

| Smell | 3.96 (0.71)a |

| Color | 4.12 (0.70)a |

| Texture | 3.27 (1.09)b |

9-point hedonic scale evaluation. *Scores with different superscripts are significantly different according to Tukey´s test at a confidence level of 95%.

Table 3 shows that texture and taste significantly influence the other sensory characteristics (smell and color) as indicated by the significant differences between the two means (p<0.05). The main sensory characteristics that influence the consumer in the global acceptability was the texture and flavor of the product.

Physicochemical and microbiological parameters during refrigerated storage

These physicochemical and microbiological parameters were analyzed over 21 days, estimated useful lifetime for vacuum-packed vegetables cooked by sous vide. The parameters evaluated are presented in Table 4.

Tabla 4. Parameters evaluated in ready-to-eat millefeuille with the addition of polyphenols.

| Parameters | Day 0 | Day 7 | Day 14 | Day 21 |

|---|---|---|---|---|

| Polyphenols (mg EAG/100 g) | 200.23 (0.85)a | 199.96 (0.69)a | 199.55 (2.03)a | 189.69 (1.40)b |

| pH | 5.25 (0.05)a | 5.42 (0.03)a | 5.40 (0.10)a | 5.50 (0.20)a |

| Color | ||||

| L* | 48.37 (1.97)a | 47.81 (0.32)a | 47.50 (0.52)a | 47,87 (1.43)a |

| a* | 21.07 (1.93)a | 19.73 (0.03)a | 18.60 (0.82)b | 16.97 (0.45)c |

| b* | 49.59 (13.18)a | 46.65 (5.20)a | 45.20 (1.23)b | 40.64 (0.94)c |

| ∆E* | - | 15.690 (9.85)a | 15.86 (11.06)a | 12.29 (9.02)b |

| C*ab | 47.82 (1.28)a | 41.62 (0.53)a | 41.53 (1.28)a | 44.03 (1.12)a |

| Texture | ||||

| Initial module (mm/mm) | 25.94 (2.68)a | 23.57 (0.05)a | 20.77 (0.10)b | 18.30 (0.61)b |

| Hardness (N) | 6.16 (0.05)a | 6.05 (0.06)a | 6.16 (0.06)a | 6.11 (0.08)a |

| Maximum deformation (mm) | 4.21 (0.40)a | 3.89 (0.26) | 3.69 (0.36)b | 2.99 (0.11)b |

| Mohos y levaduras (UFC/g) | < 10 | < 10 | < 10 | < 10 |

| Lactobacilos (UFC/g) | < 10 | < 10 | < 10 | < 10 |

| Aerobic psychrotrophic (UFC/g) | < 10 | < 10 | < 10 | < 10 |

*Average value ± standard deviation of the results (n=3). Samples with the same letter in the same column were not significantly different by the Tukey test (p<0.05).

It was observed that the polyphenol content remained constant until day 14. It was observed that the studied product did not experience changes in pH or weight (p>0.05) during the storage period. Regarding the color parameters, it was observed that the values of a* and b* remained constant until day 7. The color intensity and luminosity during storage did not show a significant difference (p>0.05) in the evaluated time. The ∆E* remained constant until day 14. Taking into account the evolution of the values, color was observed to decrease over time.

The uniaxial compression test, it was observed that the values of firmness and maximum force remained constant until day 14 and then began to decrease.

The microbiological parameters studied showed that there was no proliferation of the groups of microorganisms evaluated, possibly due to the absence of oxygen, the low refrigeration temperature, and the appropriate conditions of the sous vide cooking process. In this way, the product could be considered suitable for human consumption during the period studied.

Discussion

The ready-to-eat product obtained provides 200.23 mg GAE/100 g per serving, through the VI. In previous studies, the times and conditions of VI (vacuum and restoration, times and concentration of the impregnation solution) were determined to impregnate the sweet potato slices used in the design of the culinary preparation16. The literature shows that vegetables rich in polyphenols have a concentration ranging between 170-930 mg of GAE/100 g17. Data analysis indicated that the impregnated sweet potato represents an increase in phenolic-compound concentration over the control sample of 473%. Thus, this method could be considered as suitable for incorporating biologically active substances into vegetables, so as to facilitate the improvement of the nutritional quality by those supplements.

Although the recommended values for the population have not yet been stipulated for polyphenols, various studies state that it is necessary to increase daily consumption. Many polyphenols have free radical scavenging properties, giving them antioxidant activity, which could be related to the prevention of non-communicable diseases8. Some authors have verified the feasibility of incorporating polyphenols using VI. Moreira and Almohaimeed24 added polyphenols to healthy potato chip snacks using VI and vacuum frying technology. Tappi et al.25 used a green tea extract to enrich the apples minimally processed by VI to obtain a nutritionally fortified product. In this way, VI can be considered an effective technique to design new products with functional components.

In the study by Aviles et al.26, two products cooked by sous vide, a vegetable lasagna and a hamburger, obtained the rating "I like it slightly", results similar to those observed in this study regarding general acceptability of the product. The sensory evaluation of the main parameters that consumers judge for the acceptability of products -smell, texture, color, and taste- was carried out27. Visual appearance and color are usually the first sensory stimuli that are presented to consumers and they influence expectations about food. The visual properties can produce positive or negative sensations that lead to the acceptance or rejection of food, respectively28. Firmness is one of the main factors that consumers use to define whether a vegetable is properly cooked27. Consumers evaluated the acceptability of the texture by expressing "I do not like or dislike it", and comments such as "it feels crunchy, but some parts seemed to be raw", "it could be tenderer", "it seemed tough to me, kind of raw" were highlighted. This perception of a raw product with a tough texture could be attributed to the sous vide method, characterized by better preserving the texture of vegetables, unlike traditional cooking methods, in which the toughness constantly decreases. The acceptability of new products is determined by conditions related to food and consumers. The appearance, texture, and taste of the products are fundamental characteristics to establish favorable sensory and hedonic responses for the consumer29.

To determine the refrigerated storage time of the preparation, the parameters that determine the quality of food and affect the sensory perception and acceptability of the consumer (variation of weight, pH, color, and texture) were evaluated30. The parameters that indicate the quality and safety (microbial count) of food, as well as the compound added through VI (polyphenols), were also measured. These physicochemical and microbiological parameters were analyzed over 21 days, estimated useful lifetime for vacuum-packed vegetables cooked by sous vide31.

In this study it was observed that the polyphenol content remained constant until day 14, while Tappi et al.25. studied the quality and stability of minimally processed apples impregnated with green tea polyphenols, finding polyphenol values without significant modification until day 7 of storage.

The pH affects the properties of food and can be an indicator of growth or mortality of microorganisms, inactivation of bacterial spores, and chemical reactions such as Maillard’s30. In this study, the pH obtained did not present changes during the storage period studied. Therefore, control of effects during storage is necessary to safely produce quality and value-added products.

Conclusions

In conclusion a ready-to-eat millefeuille was designed with 220 mg of GAE/100 g of polyphenols using vacuum technologies. The developed product maintained, in general, the initial quality and safety characteristics with a commercial life of at least 14 days stored in refrigerated conditions at 3 °C. The sous vide cooking method used allowed us to improve the conservation time in refrigeration of the preparation since the microbial load was kept at safe levels. The sensory attributes of taste, smell, texture and color analyzed were accepted by consumers, with texture being the most significant parameter that influences the acceptability of the product. It would be interesting to complement these results with sensory tests and the qualitative determination of polyphenols during storage and their relationship with antioxidant activity, in addition to other bioavailability experiments. Products of nutritional quality, such as the one studied in the present work, could be an option to incorporate ready-to-eat vegetable dish preparations into the market and thus contribute to increasing the consumption of vegetables.