INTRODUCTION

Sustainable diets are defined as “diets that are culturally acceptable, accessible, economically fair and affordable, nutritionally adequate, safe and healthy, that protect and respect biodiversity and ecosystems, while optimizing natural and human resources” (1). Many fruits and vegetables, such as bananas, apples, tomatoes, lettuce, sweet peppers, pears, grapes, onions, artichokes and asparagus, produce significant amounts of waste (2). Banana peels, which are obtained as a result of the consumption or processing of bananas and have high nutritional value, cannot be utilized economically to the desired extent. Approximately 18-35 % of the banana fruit consists of the peel part (3). Biomass conversion technologies include methods such as direct combustion, airless digestion, fermentation, pyrolysis, gasification, biophotolysis, carbonization, briquetting and pelleting (4).

Paraprobiotics, known as nonviable probiotics, inactivated probiotics, totalized probiotics, or phantom probiotics, are defined as “nonviable microbial cells” (either intact or lysed) or when administered in small amounts (orally or locally) to a human or animal are crude cell extracts that provide a benefit to the consumer (5,6). Over the last decade, evidence for the beneficial effects of paraprobiotics in the prophylaxis and treatment of various pathologies, including diarrhea, colitis, respiratory, intestinal and alcohol-induced liver diseases, inflammation and allergies, has been supported by in vivo studies in mouse models and human clinical trials (7-9). Snack bars are widely consumed by consumers who need a quick source of energy due to the lack of time to eat enough (10). This research aims to develop a product with high sensory and nutritional quality to ensure that paraprobiotics can be consumed on the basis of their health-promoting effects and to contribute to environmentally friendly nutrition, which is one of the sustainable nutrition principles, while developing this product.

MATERIAL AND METHODS

This study aimed to integrate paraprobiotics, which have been proven to have many positive effects on health, into human nutrition through the evaluation of wastes within the scope of a sustainable nutrition model. In this context, the experimental process of the study, in which healthy snack bars are produced, which is aimed to be a product with high nutritional value and acceptable, was carried out in the Microbiological Analysis Laboratory of the Department of Food Engineering of Suleyman Demirel University.

RAW MATERIALS AND CHEMICALS

In this study, the raw materials that make up the snack bar were finely ground oatmeal, 100 % peanut butter, dates, raisins, carrots, bananas, coconut, flaxseed, 70 % demineralized whey powder, paraprobiotic liquid banana peel medium (in the paraprobiotic bar group; using Lactobacillus plantarum [L. Plantarum] and Lactobacillus casei [L. Casei]), and pure water (in the bar group without paraprobiotics). The bananas used in the research were purchased from local producers in Alanya, Turkey, and other raw materials were purchased from local markets in Isparta. Preparation and cooking utensils used in the production phase and chemicals and laboratory consumables used in the analysis phase were obtained from the Microbiological Analysis Laboratory of the Food Engineering Department of Suleyman Demirel University.

DEVELOPMENT OF PROBIOTIC BACTERIAL CULTURES IN BANANA PEEL MEDIA

To use banana peels as a medium, 150 g fresh yellow banana peel was cut into fine pieces and dried in an incubator at 60 °C for 24 hours. Then, 140 ml of distilled water was added to the dried banana peels at a ratio of 1/10 (dry banana/water; g/ml), and the mixture was sterilized at 120 °C for 15 minutes. After sterilization, the dried banana peels that fell to the bottom were filtered with coarse filter paper. The obtained clear supernatant was used as the medium. The pH measurement of this sterile medium was performed at room temperature (pH: 5.21). The L. plantarum and L. casei probiotic cultures used in the study were obtained from the Department of Food Engineering Microbiological Analysis Laboratory of the Suleyman Demirel University. Lactic acid bacteria (L. plantarum and L. casei) were activated in MRS broth (Biolife) medium at 30 °C for 48 hours. After the cell density of the activated cultures was adjusted with the Macfarland device, they were inoculated into banana peel medium at 1.5 x 106 cfu/ml. These media were then incubated at 30 °C for 72 hours. The count of lactic acid bacteria in the medium after incubation was determined by the smear culture method after 48 hours of incubation at 30 °C in MRS agar (Merck) medium. In the counts made after the incubation, the average of L. casei was found to be 3 x 109 cfu/ml, and the average of L. plantarum was 1.5 x 109 cfu/ml in the banana peel medium prepared by drying. Thus, it has been observed that the target bacteria number (107-1010 cfu/1 portion of the product) required for the production of paraprobiotics, which will be used in bar production and can be easily added to the amount of bar that an adult individual can consume daily, has been reached.

OBTAINING PARAPROBIOTIC FROM BANANA PEEL MEDIUM

As described above, banana peel media inoculated with L. plantarum and L. casei at a density of 1.5 x 106 cfu/ml and then incubated at 37 °C for 36 hours were pasteurized at 80 °C for 30 minutes. After pasteurization, pH measurements were made at room temperature.

PRODUCTION OF PARAPROBIOTIC BARS

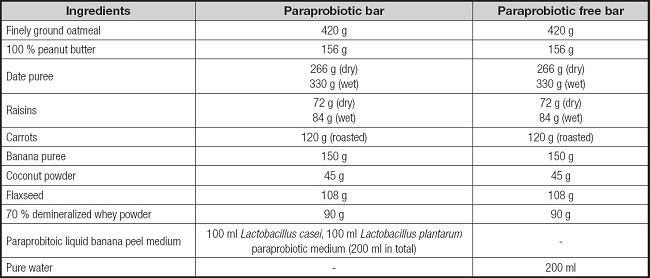

In this study, the production of snack bars with paraprobiotics added was planned. To make comparisons, two different types of snack bars, with and without paraprobiotics, were produced. While making preliminary trials, a standard bar production process was established with the aim of clearly determining criteria such as flavor and consistency compatibility of the determined materials, appropriate drying temperature and time, and the rate of liquid loss after drying. After three preliminary trials, the appropriate amount of bar materials and the appropriate production process were created for actual production. The materials used in the actual production and their quantities are shown in table I. The target number of paraprobiotics in a serving glass was determined to be 109-1010 cfu/35-40 g dried bar. This number is the range of the average amount of paraprobiotic consumed in a day in human studies with the addition of paraprobiotics. According to this calculation, when 100 ml of L. casei and 100 ml of L. plantarum-containing paraprobiotic banana peel medium were added to an average of 1,500 g of wet dough, the desired number of paraprobiotics was reached in one portion bar. All ingredients were homogeneously mixed and kneaded to obtain bar dough for both groups. The dough is divided into two different groups, with and without paraprobiotics. Both groups of wet dough were sliced and were dried at 60 °C for approximately 65 hours.

SENSORY ANALYSIS

Sensory analyses of the produced bars with and without paraprobiotics were performed with 20 panelists. Panelists consist of undergraduate and graduate students and faculty members of the Department of Food Engineering at Suleyman Demirel University. The samples were coded as 1 (with paraprobiotic) and 2 (without paraprobiotic). Panelists randomly tasted the samples in an independent environment and evaluated the criteria for stickiness, color, chewiness, flavor, adhesion to teeth, and general acceptability with scores ranging from 1 to 5 points (1: very bad, 2: bad, 3: fair, 4: good, 5: very good).

CHEMICAL ANALYSIS

Energy, protein, total fat, saturated fat, fatty acid profile, carbohydrate, total fiber, total sugar, calcium, iron, magnesium, potassium, sodium, zinc, ash, moisture, acidity and pH, total phenolic components and antiradical activity analyses of the bars were performed. Most of the chemical analyses were made by Suleyman Demirel in the form of service procurement. Oil extraction, pH, acidity, total phenolic component and antiradical activity analyses for fatty acid profiles were performed at the Microbiological Analysis Laboratory of Suleyman Demirel University.

For fatty acid profile analysis, bar samples were crushed and dried at 105 °C for 24 hours. Oils of dried bars were extracted using n-hexane and diethyl ether 1/5 (sample/solvent). After the solvents were added to the samples, they were shaken once an hour and left for 72 hours. After the obtained mixture was filtered with the help of coarse filter paper, the obtained supernatant was evaporated with the help of a rotary evaporator (Heidolph, Laborota 4000-efficient) at 70 °C, and diethyl ether and n-hexane were evaporated. The resulting oil was used for the fatty acid profile.

Total phenolic compound analysis

To extract the phenolic substances from the bar samples, 5 g were taken from each of the two samples and crushed thoroughly, and then 15-ml methanol was added. The resulting mixture was homogenized with the help of a homogenizer and then filtered with the help of coarse filter paper. The filtrate was centrifuged at 10,000 rpm for three minutes (Hettich®, Micro 120 centrifuge). The obtained supernatant was used as a sample in the analysis of total phenolic compounds. Gallic acid was used as the standard phenolic compound. Total phenolic component analysis was performed with a UV spectrophotometer device according to Singleton and Rossi, 1965 (11). Solutions were left in the dark at room temperature for two hours and then read at 760 nm. The phenolic content was calculated by multiplying by the dilution factor. Analysis results were calculated according to the calibration chart prepared using standard gallic acid solution (y = 0.009x + 0.0547). The results are expressed as mg/g gallic acid equivalent (GAE). The total phenolic substance calibration graph of the snack bar samples is shown in figure 1.

Determination of 2,2-diphenyl-1-picryl-hydrazyl (DPPH) free radical scavenging activity analysis results

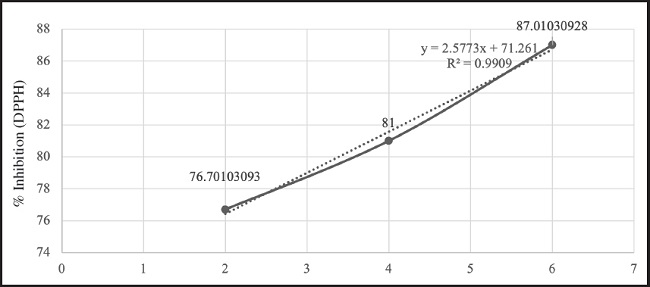

The hydrogen bonding ability of the compounds in the extracts obtained by the extraction method described in the section total phenolic component analysis was calculated using the 2,2-diphenyl-1-picryl-hydrazil (DPPH) free radical scavenging activity assay published by of Dorman et al. (2003) (12). As a control, methanol was used instead of the phenolic extract. DPPH free radical scavenging activity was calculated using the following formula, and the results are given as % inhibition and ascorbic acid (AA) equivalents. To express the results as AA equivalents, a calibration chart created with the absorbance values read at 517 nm of AA solutions prepared at different concentrations (0 mg/ml, 2 mg/ml, 4 mg/ml) was used (y = 2.5773x + 71.261). The AA antioxidant activity calibration chart of snack bar samples is shown in figure 2.

Figure 2. Ascorbic acid equivalent antioxidant activity graph (mg/g). DPPH: 2,2-diphenyl-1-picryl-hydrazil.

% Inhibition (DPPH) = [(Abs Control - Abs Sample)/Abs Control]*100

Abs. sample: for example, absorbance value read at 515 nm

Abs. control: the absorbance value of the control read at 515 nm

Acidity and pH analysis

For acidity determination, 25 ml of distilled water was added to 5-g sample, the mixture was shaken frequently and passed through coarse filter paper, and the resulting clear solution was titrated against 0.01 N NaOH solution with phenolphthalein indicator. Acidity was determined in terms of tartaric acid (13). For pH measurement, 100 ml of deionized water was added to 10-g sample and mixed for five minutes in a magnetic stirrer. The pH value of the filtrate filtered with coarse filter paper was measured with a pH meter (WTW, inoLab®, Germany) (14).

TPA TEXTURE ANALYSIS

The AACC Standard Method No. 74-09 was used in the determination of the breaking strength of the bar samples, and the breaking force value was determined as (F, g) according to the three-point fracture test technique by using a texture analyzer (TA-XT plus, Stable Micro Systems, United Kingdom) (15). The preliminary speed was 1 mm/s, and the test speed was 5 mm/s. The distance between the two supports was determined as 4 cm.

COLOR MEASUREMENT

Color measurements of the snack bars were performed using the Minolta Chroma Meter (CR-400; Konica Minolta, Inc.). L* (brightness), a* (red, green) and b* (yellow, blue) values in snack bar samples from two separate points using a white standard calibration plate (Y = 92.7, x = 0.3160, y = 0.3321) as background measured. The hue (color essence) value was calculated by the arctan (b*/a*) formula (16).

YEAST MOLD COUNT

Total yeast-mold counts were made on yeast extract glucose chloramphenicol agar (YGC) medium by incubation for 96 hours at 30 °C according to the smear culture count method.

STATISTICAL ANALYSIS

Experiments were carried out with two replications, and the Minitab statistical program, version 21.2.0, was used in the statistical analysis of the data obtained as a result of the research. Data means of bar samples were compared with Student's t-test. Significant data averages are shown in the tables. Statistical differences with p < 0.05 were considered as significant.

RESULTS

INCREASE IN LACTOBACILLUS CULTURES AND CHANGE IN MEDIA pH

Lactobacillus cultures (L. casei and L. plantarum) inoculated on banana peel media at 1.5 x 106 cfu/ml were incubated at 30 °C for 72 hours. The count of lactic acid bacteria in the medium was determined by the smear culture method after 48 hours of incubation in MRS agar (Merck) medium at 30 °C. In the counts made after the incubation, the average of L. casei was found to be 3 x 109 cfu/ml, and the average of L. plantarum was 1.5 x 109 cfu/ml in the banana peel medium prepared by drying. Increase of Lactobacillus cultures on banana peel media is shown in figure 3. While the initial pH of the banana medium was 5.22, it was 3.97 after incubation with L. casei and 3.87 after incubation with L. plantarum.

SENSORY ANALYSIS RESULTS

There was no statistically significant difference between the sensory score averages of stickiness, color, chewiness, flavor, adhesion to teeth and general acceptability between the bars with and without paraprobiotics (p > 0.05). In both bar types, the stickiness criteria of the bars received the highest scores.

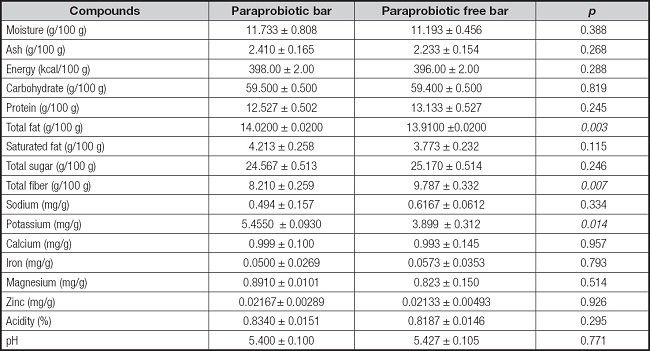

CHEMICAL ANALYSIS RESULTS

The chemical analysis results of the bar samples with and without paraprobiotics are shown in table II. The total fiber content of the bar with paraprobiotics was 8,210 ± 0,259 g/100 g, and the total fiber content of the bar without paraprobiotics was 9,787 ± 0,332. The difference between the fiber values of the two bars was statistically significant (p < 0.05). The potassium content of the bar with paraprobiotics was 5.4550 ± 0.0930 mg/g, and the potassium content of the bar without paraprobiotics was 3.899 ± 0.312 mg/g. This difference between the two bars was statistically significant (p < 0.05). The total fat and the percentages of caproic acid, caprylic acid, capric acid, lauric acid and myristic acid in the bars with paraprobiyotics were significantly higher than in bars without paraprobiotics (p < 0.05). Linoleic acid and cis-11-aicosenoic acid (gonodoic acid) percentages were found to be significantly lower in bars with paraprobiotics than in bars without paraprobiotics (p < 0.05).

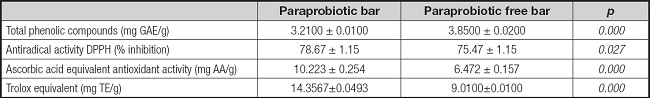

Total phenolic compounds and antiradical activity results

The total phenolic compounds and antiradical activity results of the bars are shown in table III. The total phenolic compounds of the bars with paraprobiotics was 3.2100 ± 0.0100 mg GAE/g, and the total phenolic compounds of the bars without paraprobiotics was 3.8500 ± 0.0200. The antiradical activity of the bars with paraprobiotics was 78.67 ± 1.15 (DPPH% inhibiton), 10.223 ± 0.254 mg AA/g and 14.3567 ± 0.0493 mg trolox equivalent (TE)/g, and the antiradical activity of the bars without paraprobiotics was 75.47 ± 1.15 (DPPH% inhibition), 6.472 ± 0.157 mg AA/g and 9.0100 ± 0.0100 mg TE/g. The total phenolic compounds and antiradical activity values (DPPH%, AA equivalent and TE) differences between the bars were statistically significant (p < 0.05).

COLOR AND TEXTURE MEASUREMENT RESULTS

The color measurement values of the bars are also evaluated. The b* (yellowness) values of the bars with and without paraprobiotics were 6.81 ± 1.17 and 8.145 ± 0.531, respectively, and this difference between the two bars was statistically significant (p < 0.05). The hardness value of the bar sample with paraprobiotics was lower than the hardness value (3,862 ± 507 vs 4,571 ± 1,369) and the fragility value (39.868 ± 0.792 mm vs 40,293 ± 0.544 mm) of the bar sample without paraprobiotics. These differences were not statistically significant (p > 0.05).

YEAST-MOLD COUNT RESULTS

Yeast-mold was not detected in the microbiological analyses of the bars with and without paraprobiotics, which are ready for consumption after production.

ENERGY AND NUTRIENT CONTENT RESULTS

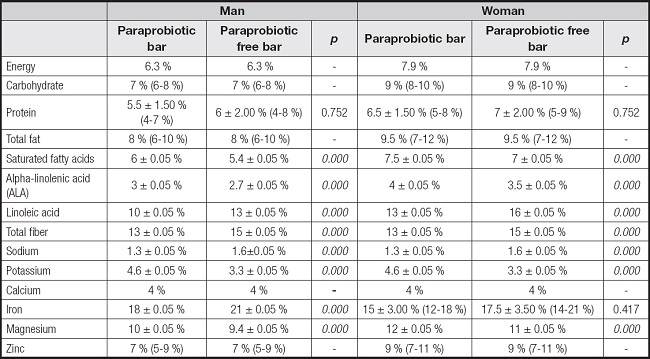

The daily energy and nutrient meeting percentages of a moderately active healthy adult man and woman of a serving (40 g) bar with and without paraprobiotics are shown in table IV. When the menu sample recommended for a healthy adult male and female from the Turkish Dietary Guidelines is examined, it is seen that a portion of paraprobiotic bar can meet the need for snacks alone or in combination with another food (17).

DISCUSSION

L. casei is a microorganism that produces lactic acid during the fermentation process. As a result of lactic acid accumulation, the pH value of the fermentation medium gradually decreases (18). Banana peel is a suitable food for microorganism fermentation due to its high carbohydrate, protein, and fiber contents, as in many other fruits and vegetables themselves and their skins.

The difference between the fiber values of the two bars was statistically significant (p < 0.05). The reason for this difference may be the presence of bioactive postbiotics such as functional proteins/enzymes and bacteriocin produced by live microorganisms before inactivation in the banana peel medium contained in the bar with paraprobiotics, and these substances breakdown lignocellulosic substances. In a study conducted to compare the extracellular proteolytic, cellulolytic and hemicellulolytic enzyme activities of seven L. plantarum strains isolated from Malaysian foods, L. plantarum strains studied on palm kernel cake biomass have been shown to produce versatile nonmulticellular hydrolytic enzyme activities from acidic to alkaline pH conditions (19).

The potassium content differences between the two bars may be because the potassium in the extracted banana peel is much higher than other minerals and passes into the prepared medium.

The total fat and the percentages of caproic acid, caprylic acid, capric acid, lauric acid, and myristic acid in the bars were significantly different (p < 0.05). The higher amounts of total fat and mentioned fatty acids in the paraprobiotic bar were due to the presence of postbiotics such as cell wall-bound biosurfactants, lipopolysaccharides, lipoteichoic acids, structural components such as short-chain fatty acids or synthesized metabolites (20,21). Linoleic acid and cis-11-aicosenoic acid (gonodoic acid) percentages were found to be significantly lower in bars with paraprobiotics than in bars without paraprobiotics (p < 0.05). Aziz et al. stated that L. plantarum is a probiotic bacterium capable of converting growth-inhibiting free polyunsaturated fatty acids, and it has been reported that the conversion reactions of linoleic acid to other fatty acid metabolites in L. plantarum 13-3 are isomerization, dehydrogenation and reduction. The putative linoleate isomerase and dehydrogenase that catalyze the respective reactions were identified using the whole genome sequence of L. plantarum 13-3. In other words, these enzymes of L. plantarum may have caused a slight decrease in the amount of linoleic acid and gonodoic acid by causing such a reaction in the banana peel medium and bar medium containing paraprobiotics (22).

Nadeem et al. produced snack bars using four different ratios of palm paste, dried apricot paste, skimmed milk powder, roasted chickpea flour, peanut and sodium chloride. The mineral ranges of the produced formulas were as follows: sodium = 22.73-23.36; potassium = 637.64-642.12; calcium = 101.02-102.59; iron = 4.85-5.05; and zinc = 2.65-2.75 mg/100 g (23).

In a study by Sun-Waterhouse et al., in which they wanted to develop snack bars with high dietary fiber and polyphenol content, the snack bar base was formulated with or without fiber (control bar) or fiber (inulin or apple pulp bar). The total amount of fat in 100 g of snack bars was 9.59 ± 0.03 and 8.70 ± 0.11 g (24).

Silva de Paula et al., in a study where they wanted to produce cereal bars containing high levels of fiber and omega 3 using functional ingredients, the materials used for bar production were flaxseed meal, flaxseed meal, oats, soybean oil, corn glucose, brown sugar, cashews, dried bananas and water. Four different formulations were created in which flaxseed and flaxseed flour were used at rates of 0 % (F1), 5 % (F2), 10 % (F3) and 20 % (F4). The linoleic acid contents of these bars are F1, F2, F3, and F4, and the linoleic acid amounts in 100 g are 3.9, 3.4, 2.8, and 2.6 g, respectively. The amount of alpha linolenic acid is 0.30, 1.3, 2.1, and 4.4 g in the same order (25).

As a result of the literature reviews, in general, the bar with paraprobiotics is high in protein and fiber; total fat and total sugar content is low; mineral content is similar, energy, carbohydrate and linoleic acid content is similar; and alpha linolenic acid content is low. The ingredients vary according to the variety and amount of raw materials and the production targets of the bars.

The total phenolic compounds and antiradical activity values (DPPH%, AA equivalent and TE) differences between the bars were statistically significant (p < 0.05). The antiradical activity of the produced paraprobiotic bars is generally expected to be directly proportional to the total phenolic substance content. However, phenols are not the only group of molecules that provide antiradical activity in the bar with paraprobiotics. Aydin et al. evaluated the antioxidant activity of postbiotics and paraprobiotics in lactic acid bacteria isolated from 12 different handmade fermented sausage samples and determined that the antioxidant capacity of postbiotics and paraprobiotics was strain-dependent and that postbiotics had higher antioxidant activity than paraprobiotics (26). In other words, as a result of the study, the antiradical activity of the bar with paraprobiotics was found to be significantly higher than that of the bar without paraprobiotics, which may be due to the antioxidant effect of paraprobiotics and postbiotics.

Rajagukguk et al., in a study where they wanted to develop pulse-based snack bars combined with probiotics, used chickpeas or green lentils, oatmeal, high fructose corn syrup, dried cranberries, almond pieces, honey, puffed rice, vanilla essence and powdered cinnamon in bar production. After cooking, they added a mixture of dark chocolate containing 55 % cocoa and probiotic culture L. plantarum. The total phenolic content of the chickpea and green lentil-based snack bars produced with probiotics was 305.90 ± 3.02 and 277.20 ± 5.59 mg GAE/100 × g for the green lentil bar and 293.16 ± 4.05 and 210.01 ± 1.63 mg GAE/100 × g for the chickpea-based bar at 0 and 1 months, respectively. TE (mg TE/100 g) obtained by the DPPH method of chickpea and green lentil-based probiotic snack bars produced 393.74 ± 4.45 and 277.40 ± 4.75 for chickpea-based bars and 434.65 ± 3.11 and 401.94 ± 1.55 for green lentil-based bars at 0 and 1 months, respectively (27).

According to the definition in the Turkish Food Codex Regulation on Nutrition and Health Claims Annex-1, Nutrition Declarations and Conditions of Declaration, bars with and without paraprobiotics are classified as “low”; “low sodium”; “containing significant” iron, magnesium, zinc and potassium; “protein added, “protein source” or “protein containing”; and “high fiber” products. Compared to other studies, it was a nutritional product containing phenolic substances with significant antiradical activity. The fact that the paraprobiotic bar is a protein source makes it functional for individuals who exercise and for groups and situations with increased energy and protein needs (elderly, cancer patients, adolescents, burn patients, etc.). The fact that bars are a source of protein comes from whey powder and peanut butter.

CONCLUSIONS

With this study, the desired goal to be achieved in terms of nutritional value is to ensure that a healthy adult individual consumes 40 g of paraprobiotic snack bar, both to take paraprobiotics and to meet the need for at least one snack rich in nutrients. The obtained paraprobiotic bar has become a preferred sensory product that is rich in energy and some nutrients and will contribute to functional nutrition due to its paraprobiotic content. In addition to containing paraprobiotics, features such as high fiber and protein content, some essential fatty acids, no added sugar, low sodium and high preference for some sensory criteria make it suitable for elderly individuals, athletes, children and adolescents, and patients with malnutrition and diabetes, making it preferable by groups with chronic metabolic diseases such as obesity. While the production of bars with paraprobiotics contributes to sustainable nutrition, it has been found that when evaluated in terms of nutrients, it has similar characteristics to a bar without paraprobiotics. It has been observed in the literature that paraprobiotics are not added to snack cereal products to enrich these products. In all studies, it was emphasized that studies should be carried out to enrich the products with paraprobiotic added. This study is based on the inclusion of paraprobiotics in a different product and the evaluation of waste while producing such a product. More studies are needed on the development and effects of paraprobiotic products.